Precision Machining Services for Superior Part Accuracy

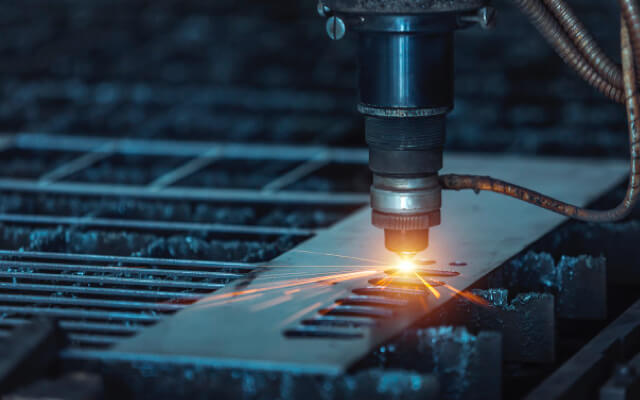

Manufacturing industries continue to evolve as technology pushes standards higher for accuracy and performance. Products today must meet strict specifications to ensure reliability, safety, and durability. This is where precision machining services play a major role in transforming raw materials into exact components that match digital designs. Using advanced CNC milling and turning, manufacturers can achieve repeatable results with tight tolerances and smooth finishes. In this article, we will explore the process of precision machining, its advantages, and why it has become a foundation of modern production.

What Is Precision Machining?

Precision machining is a process that removes material from metal or plastic to create parts that match detailed engineering drawings. The operation is controlled by CNC machines that follow programmed instructions based on CAD files. This allows every cut, drill, and movement to be performed with accuracy.

Compared to traditional manual machining, precision machining reduces human involvement and improves consistency. Whether producing one custom prototype or a full production batch, the same level of quality can be maintained throughout the project.

The Power of CNC Milling and Turning

CNC milling and turning are the most widely used techniques in precision machining. Milling uses rotating tools to carve complex shapes and features, while turning rotates the workpiece to produce round or symmetrical components.

These two methods work together to support a wide variety of designs. Industry data shows that CNC machining can improve dimensional accuracy by more than 65 percent when compared to older mechanical processes. This improvement reduces errors and increases production efficiency for manufacturers.

Why Accuracy Is Essential in Manufacturing

Precision is not only about meeting design requirements. It also affects safety, product lifespan, and customer trust. A minor flaw in a machine component can cause breakdowns, production delays, or even safety hazards.

Precision machining ensures that parts fit correctly during assembly and function as expected in real-world use. This reduces stress on machines, limits wear and tear, and improves the overall performance of equipment and products.

Materials Used in Precision Machining

Precision machining services work with a broad range of materials to meet different industrial needs. Common metals include aluminum, stainless steel, brass, and titanium. These materials are selected for their strength, corrosion resistance, and machinability.

Engineering plastics such as ABS, nylon, and PEEK are also popular choices. Plastics are lightweight, cost-effective, and ideal for applications requiring electrical insulation or chemical resistance. The ability to machine multiple materials allows manufacturers to support industries with diverse technical requirements.

Quality Control and Production Standards

Quality control is a key element of precision machining. During production, parts are measured using tools such as calipers, micrometers, and coordinate measuring machines. These inspections confirm that each component meets the required tolerances.

Professional facilities follow strict quality standards and documentation procedures. This approach minimizes defects and ensures that finished products match design expectations. Quality assurance also builds confidence between manufacturers and customers.

The Importance of Skilled Facilities

A professional machining shop combines advanced CNC equipment with trained technicians who understand both materials and machine programming. These specialists study engineering drawings, select appropriate tools, and set machine parameters for optimal results.

Their experience allows them to manage complex projects that require high accuracy and tight tolerances. Skilled teams also help reduce production time while maintaining consistent quality across every batch.

Industries That Depend on Precision Machining

Precision machining is used across many industries that demand high performance and reliability. Aerospace companies rely on it for aircraft components that must meet strict safety requirements. The medical industry uses it for surgical tools and implants that require smooth surfaces and precise dimensions.

Automotive manufacturers depend on precision machining for engine parts, gears, and braking systems. Electronics companies also benefit from precision machining when producing connectors and housings that must fit perfectly. As technology advances, the demand for smaller and more complex parts continues to increase.

Cost Benefits and Long-Term Value

Although precision machining may involve higher upfront investment, it provides long-term value. Reduced material waste, fewer production errors, and lower maintenance costs lead to significant savings over time.

High-quality parts also improve product reliability and customer satisfaction. Businesses that invest in precision machining gain a competitive advantage by delivering durable and accurate products that meet market expectations.

A Conversational Look at Precision Machining Services

When you look at everyday products, from medical devices to industrial machines, precision machining services are working behind the scenes. These processes ensure that every part fits correctly and performs its function without failure. Without precise manufacturing, industries would struggle to meet safety and performance goals. Choosing advanced machining solutions is a step toward better quality and long-term success.

Conclusion

Precision machining services are essential for producing accurate and dependable components in modern manufacturing. Through CNC milling and turning, manufacturers achieve consistent results across a wide range of industries, including aerospace, medical, automotive, and electronics. These services improve efficiency, reduce errors, and support innovation in product development. By working with a professional machining facility, businesses can ensure their parts meet strict quality standards while remaining cost-effective and reliable. In a competitive industrial world, precision machining continues to be a key driver of success.

Frequently Asked Questions

1. What is the main purpose of precision machining services?

The main purpose is to create highly accurate parts that meet exact design specifications using CNC technology.

2. Can precision machining be used for both prototypes and mass production?

Yes, CNC machining supports custom prototypes, small batches, and large-scale production with the same level of accuracy.

3. How does precision machining improve product durability?

By maintaining tight tolerances and reducing defects, precision machining creates parts that fit properly and perform reliably over time.